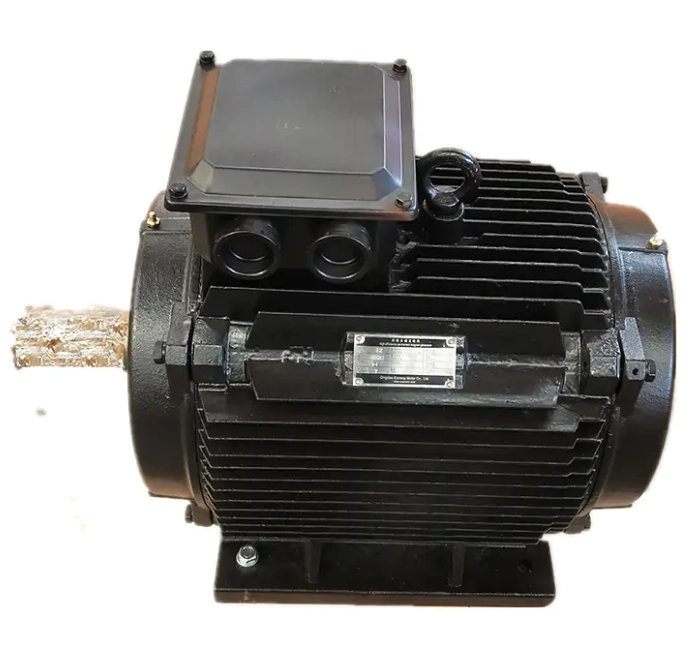

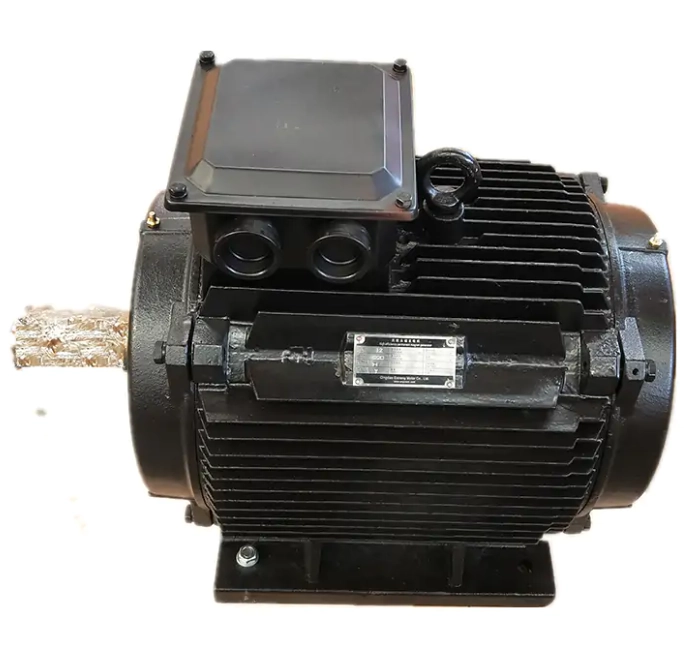

Permanent magnet synchronous motors (PMSMs) are becoming popular in many industries because they work well and save energy. These motors are used in things like water and wind power systems, where their strong performance and dependability matter a lot. In wind turbines, PMSMs help use energy better and improve how the system runs, which cuts down on upkeep costs. In water power systems, they boost how efficiently energy is turned into power, making them a top pick for today’s power setups. Why? Because these motors are small, and they don’t need a ton of fixing. If you’re trying to keep up with motor trends, knowing what’s hot with permanent magnet synchronous machines can help you pick the right stuff. One company leading the way is Qingdao Enneng Motor Co., Ltd. They’re a big-deal company that makes all sorts of permanent magnet motors. Their stuff is built to work great and be kind to the planet. Wanna know more? Check out their product center or their About Us page.

Growing Demand for Efficient Motors in Industrial Applications

Industries are picking permanent magnet synchronous motors (PMSMs) more and more. Why? They work great and save energy. With a big push for greener, energy-saving systems, PMSMs are popping up in all sorts of places, like factories and power plants. These motors run smoothly, use less power, and keep costs low. They’re perfect for spots where saving energy matters most.

Benefits of PMSMs Over Traditional Induction Motors in Industry

PMSMs beat old-school induction motors, especially when it comes to saving power. Induction motors lose energy in the rotor part. But PMSMs use fixed magnets instead. This setup cuts out extra energy waste. So, for factory machines where power use affects costs and green goals, PMSMs are a smarter choice.

Impact of Government Policies on Industrial Motor Adoption

Government rules pushing for energy savings and less pollution are speeding up PMSM use. These rules get tougher on energy use and carbon output. Industries want motors that meet these rules, work better, and cost less to run. As the rules keep tightening, more places will likely turn to PMSMs. They help make systems greener and more efficient.

Advancements in Motor Efficiency and Design

Focus on High Power Density and Compact Designs?

Saving space is a big deal, whether it’s in a car or a factory machine. Companies are making permanent magnet synchronous machines that pack a big punch in a tiny size without losing any power. The TYB Series Standard Type Permanent Magnet Motor uses high-efficiency NdFeB permanent magnet to cut down on energy loss while staying small—perfect for tight spots.

Innovations in Cooling Techniques for PMSMs?

Keeping motors cool is tricky when they’re working hard. New tricks like water-cooled cases or built-in heat sinks stop permanent magnet synchronous machines from getting too hot. These help the motor run great for a long time, even in tough jobs like textile machines or mining gear.

Use of Advanced Materials to Enhance Performance?

Using fancy magnets like Neodymium-Iron-Boron (NdFeB) is a game-changer. These magnets make strong fields with less bulk, so the motor has more kick. The TYP Series General Type Permanent Magnet Motor hits over 95% efficiency and 98% power factor, thanks to these cool materials.

Expansion Across Industrial Automation Applications

Adoption of PMSMs in Robotics and CNC Machines?

Robots and super-precise machines need motors that don’t wobble. Permanent magnet synchronous machines keep steady speeds no matter the load, so they’re awesome for robot arms or CNC tools that need to be spot-on. In jobs like tire-making or air compressors, energy-saving models with VFD cut power use while staying smooth.

Role of PMSMs in Energy-Efficient Manufacturing Systems?

Factories want to save cash on power while making more stuff. Swapping old motors for permanent magnet synchronous machines in things like conveyor belts or fans can slash electric bills. ENNENG permanent magnet motors are used in big-name companies in gold mines, coal mines, and tire plants, showing they really work in all kinds of places.

Increasing Use of PMSMs in Offshore Drilling Platforms

Offshore drilling platforms need motors that are super reliable and work well in tough, far-off places. Permanent magnet synchronous motors (PMSMs) fit the bill perfectly. They deliver strong power even at low speeds. With PMSMs, there’s no need for extra gear parts, which boosts efficiency and cuts down on breakdowns. This is key for platforms way out at sea, where fixes are hard to do.

Benefits of PMSMs in Offshore Drilling Operations

Drilling at sea means motors face rough stuff like salty water and wild weather. PMSMs shine here with their trusty performance and energy-saving design. They help keep maintenance costs low and reduce time offline. Their sturdy build keeps things running smoothly, even in remote spots where quick repairs aren’t an option. This makes them a big win for drilling platforms far from shore.

Enhancing Performance and Efficiency on Offshore Platforms

In offshore energy setups, PMSMs help make power systems work better. They improve how platforms handle energy storage and management. By using PMSMs, platforms can keep a steady, dependable energy supply. This is super important in far-out ocean spots, where solid energy systems are critical for safe and productive drilling work.

Technological Innovations in Control and Drive Systems

Development of Sophisticated Inverter Technologies?

New inverters let you control permanent magnet synchronous machines super precisely, even when the job changes a lot. They make startups smooth, cut down on weird vibrations, and keep the motor safe. That means the motor lasts longer and works better in all sorts of places.

Advancements in Sensorless Control Methods?

Sensorless controls are cool because they don’t need extra gadgets to track the rotor. They guess its spot using electrical signals, which means fewer parts to break. This makes permanent magnet synchronous machines more reliable for stuff like oil pumps or water plants where downtime’s a big no-no.

Rising Demand for Low Maintenance and Durable Motors

Importance of Maintenance-Free Operation in Industrial Settings?

Stopping work costs money. That’s why factories love motors that barely need fixing. Permanent magnet synchronous machines with high-reliability imported high-speed oil-contained bearings don’t wear out fast, unlike old motors with brushes or weak bearings.

Impact on Lifecycle Cost Reduction?

These motors might cost more upfront, but they save big over time. Less fixing and lower power bills mean the total cost drops a ton. That’s a win for bosses watching their budgets and wanting long-term savings.

Influence of Local Manufacturing Policies on Market Expansion?

Big plans like “Made in China 2025” or Europe’s Green Deal are pushing local companies to make and use these motors. They give money and support to build better tech, which helps companies like Qingdao Enneng Motor Co., Ltd. grow fast in places ready for new motor solutions.

FAQ

Q1: What makes a permanent magnet synchronous machine different from other motor types?

It’s got higher efficiency than regular motors and works great under different loads without needing extra gear.

Q2: Can permanent magnet synchronous motors meet the demands of industrial applications?

Yup! These motors shine in factory equipment with a solid fit for tough industrial jobs, offering good efficiency and fewer upkeep needs

Q3: How does sensorless control benefit industrial users?

It skips mechanical parts like encoders, so there’s less to fix. It uses smart math to track the rotor, keeping things accurate and reliable.

Q4: Are there customizable options available if I need a specific type of motor?

Totally! You can check out options for custom permanent magnet synchronous machines to fit your needs.