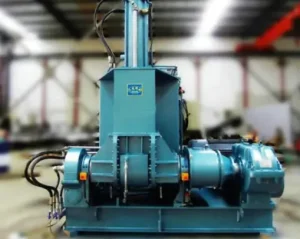

Blending rubber compounds in a steady and quick manner can truly shift the quality of your final products, making everything from tires to seals much more reliable. If you’re on the hunt for motors that offer firm torque, gentle running, and far less upkeep, then a direct drive permanent magnet motor deserves your attention, especially since it can handle tough jobs with ease. Whether it’s powering rubber mixing machines or fitting into vast factory lines, picking the ideal motor not only smooths out your daily tasks but also helps keep expenses down in the long run. You might want to dive deeper into industrial motor solutions, where you’ll find out how clever designs solve everyday production headaches that many face.

Why Choose Direct Drive Motors For Rubber Mixing?

The shift away from old belt-driven setups toward direct drive motors has really shaken up the way rubber mixing machines function these days, bringing in a level of simplicity and power that’s hard to beat. Unlike those traditional systems that rely on belts and gears, direct drive motors connect straight to the mixing chamber itself, and by doing so, they eliminate the middle parts that often lead to wasted energy and constant repairs.

Smooth Torque Delivery

With direct drive motors, you get torque that’s delivered evenly no matter the speed, which is a big win for any rubber mixing machine because it ensures the material blends uniformly without any risky hot spots or uneven curing later on. This evenness shines especially when you’re handling thick, sticky compounds that tend to resist in regular setups, and as a result, it spares the paddles and shafts from extra stress, allowing your entire mixer to serve you longer without breaking down.

Energy Efficiency And Cost Control

Since there’s no loss through mechanical bits like belts or gears, direct drive motors tend to run with much better energy use, meaning you pull more work from every bit of power you feed them. In the span of just a few months, especially in busy rubber production spots, these efficiencies can cover the upfront costs, turning what seems like an investment into real savings that add up over time.

How Do Direct Drive Permanent Magnet Motors Work?

These permanent magnet motors rely on powerful magnets to create a magnetic field that teams up with electrical currents to spin things around, and in direct drive versions, this spinning action links right up to the machine’s parts without any detours.

Reduced Maintenance Burden

Having fewer parts in motion translates to fewer fixes needed overall, which is vital for a rubber mixing machine where even short stops can throw off your whole schedule. Without belts in the picture, you dodge issues like slipping or snapping, and that means no more fussing with tension adjustments that eat into your productive hours.

High Reliability Under Continuous Load

Mixing in factories often means running for hours without a break, but direct drive motors hold steady on speed and torque even when the load is heavy and ongoing, ensuring the rubber compound keeps moving smoothly. This kind of dependability lowers the amount of wasted material and helps every batch match the last, keeping quality high day in and day out.

What Are The Key Benefits For Your Production Line?

Opting for direct drive motors goes beyond just the motor alone; it uplifts the entire flow of production, making operations feel more seamless and effective.

Compact And Space-Saving Designs

Often, direct drive motors take up far less space than those bulky belt systems of the past, freeing up valuable floor area for additional tools or allowing for snugger arrangements in crowded factories. Even with their smaller size, they don’t skimp on strength, slipping neatly into existing rubber mixing machines and making upgrades feel straightforward.

Reduced Noise And Vibration

Fewer moving elements mean shakes and sounds drop way down, which not only makes the workplace more pleasant for everyone but also lessens wear on the machinery over the years. In the world of rubber processing, keeping vibrations low is key because too much jiggling can sneak air bubbles into the mix or cause uneven blending that ruins the final product.

Precision Speed Control

What sets direct drive motors apart is their ability to tweak speeds with exact care, which proves essential for delicate rubber compounds that need a gentle start before speeding up for the finish. This fine control not only saves on power but also protects the materials from breaking down too soon, preserving their quality through the process.

How Do You Integrate Direct Drive Motors Into Existing Systems?

You don’t always have to swap out the whole setup; plenty of rubber mixing machines can welcome added direct drive motors with a bit of smart fitting.

Assessing Mechanical Compatibility

Start by checking things like shaft sizes, flange shapes, and mounting spots before any upgrade, as direct drive motors usually come in easy-to-assemble modules that cut down on install time compared to overhauling everything.

Electrical And Control Considerations

For permanent magnet motors to shine, they pair best with matching controllers that handle torque and speed just right, so seek out ones that blend smoothly with your plant’s main brains or automation gear. Today’s models can even mimic older belt behaviors while stepping up responsiveness and overall savings, making the transition feel natural.

What Maintenance Practices Keep Direct Drive Motors Performing?

Though these motors ask for minimal care, a few simple habits can ensure they keep going strong for years.

Monitor Bearings And Temperature

Give the bearings a regular once-over for any wear signs, since without belt cushioning, they bear the brunt of the load, and built-in heat sensors can flag troubles early before they turn into big problems.

Inspect Electrical Connections

Wires that loosen or rust can dim performance, so with direct drive motors depending on solid power for their torque magic, a quick check every couple of weeks prevents those unwelcome pauses in your day.

Lubrication And Cleaning

Most units seal up tight and need little grease, yet wiping away dust from vents maintains good cooling, and in sticky rubber mixing environments, clearing off any clung-on bits from outside surfaces keeps everything running clean and efficient.

Practical Examples Of Direct Drive Motor Advantages

Take high-output rubber tire factories, for instance, where direct drive motors have slashed energy needs by up to 15% each shift, and workers rave about the smoother blends that lead to fewer rejected batches. In handling smaller compound loads, they lock in steady shear to shield delicate additives from harm, while shops retrofitting older rubber mixing machines often enjoy a quick boost in performance without the expense of all-new equipment.

Conclusion

All in all, direct drive permanent magnet motors deliver clear gains to rubber mixing operations, from slashing upkeep needs and boosting energy smarts to providing even torque and freeing up space. No matter if you’re setting up a fresh rubber mixing machine or updating an old one, the perks stand out: uniform mixing results, dependable performance, and minimal interruptions. For specs or advice tailored to you, browse through industrial motor solutions to discover units that match your setup perfectly, and see how the right direct drive motors can elevate your daily compound production to new levels of ease and effectiveness.

Qingdao Enneng Motor Co., Ltd. focuses squarely on powering the heavy-duty machinery that drives primary industries.Their team has dedicated itself to meet industrial demands, concentrating on solving core industrial challenges: improving transmission efficiency, boosting system reliability, and cutting down on energy use. This practical, application-oriented approach is reflected in their product development, making them a go-to resource for engineers looking for durable and effective motor solutions for their most critical machinery.

FAQ

Q1: What is a direct drive permanent magnet motor?

A: It is a motor that uses permanent magnets to generate rotation, directly coupled to the machine’s moving parts for efficient torque delivery.

Q2: Can direct drive motors be installed on existing rubber mixing machines?

A: Yes. Many models are designed for retrofitting, provided mechanical and electrical compatibility is checked.

Q3: How do these motors improve rubber mixing quality?

A: They deliver smooth, consistent torque that prevents hotspots, reduces batch rejects, and maintains compound uniformity.

Q4: What maintenance is required for direct drive motors?

A: Regular bearing checks, electrical inspections, and surface cleaning are typically sufficient for reliable operation.

Q5: Are direct drive motors energy-efficient?

A: Yes. With fewer mechanical losses, these motors often consume less energy compared to traditional belt-driven systems while maintaining output.