Swapping an aging induction motor for a permanent-magnet synchronous motor often comes down to one worry: will it fit the existing base and coupling. In many cases the answer is yes, because modern PMSM models follow common IEC frame sizes and mountings. You gain higher efficiency, a stronger power factor, and a lower temperature rise while keeping the footprint familiar. This guide shows how to plan the swap, what to check on site, and how to keep commissioning quick and low-risk.

What Makes a PMSM a Drop-In Replacement?

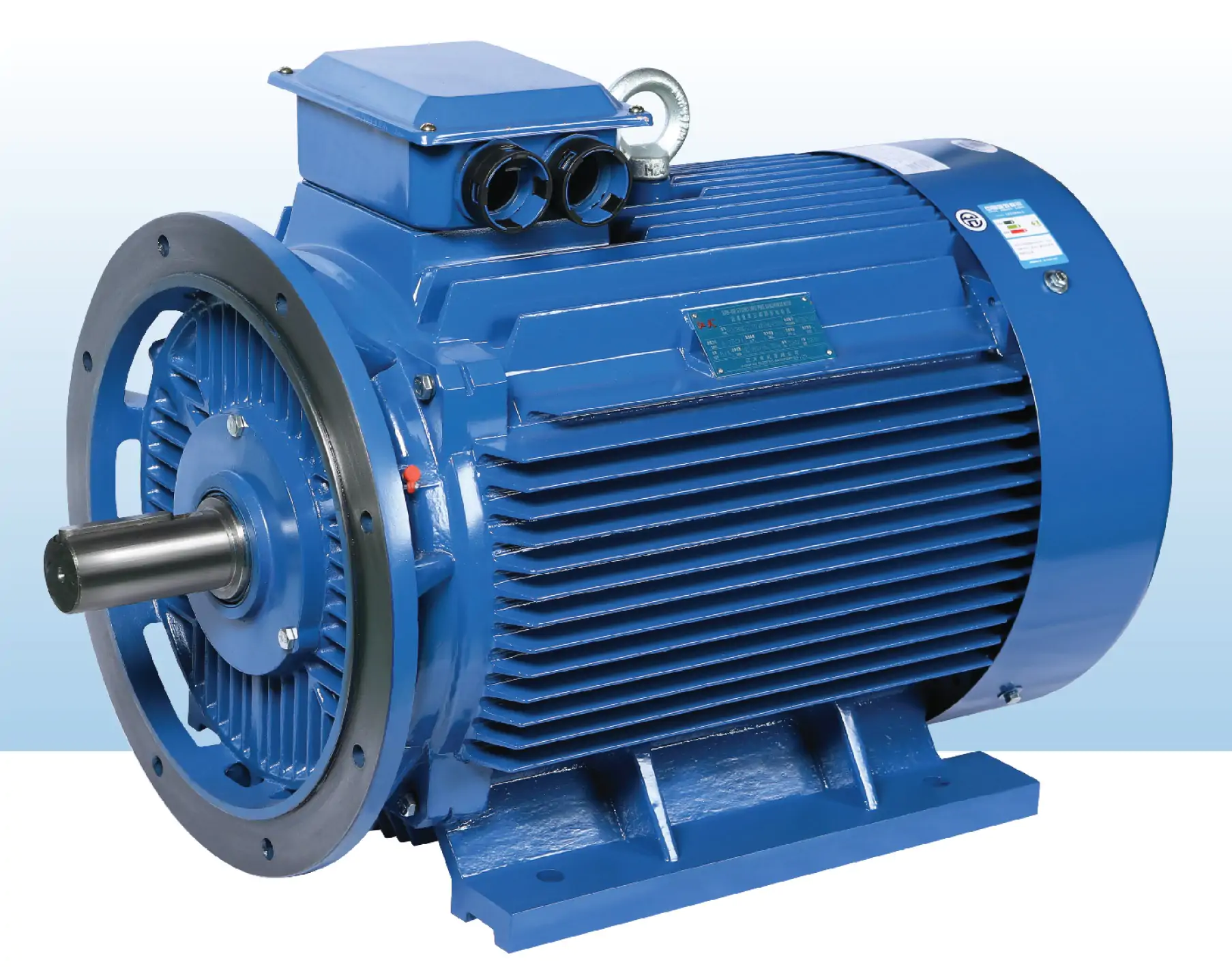

Before any wrench work, you want proof that the new unit fits and runs in your electrical window. Modern PMSM designs keep the same seat number and bolt pattern as standard asynchronous motors up to common frame sizes, with mounting forms such as IMB3, IMB5, and IMB35. That mechanical match means you can replace induction motor with PMSM without re-machining bases in most cases; note that some models can be longer in body length, so check the outline drawing.

Shared Frame Standards and Interchangeability

PMSM products follow IEC installation dimensions and GB30253 efficiency grades, with foot or flange mounting options. In typical outputs below 315 kW, the same motor seat number allows direct changeover to PMSM from an induction motor, keeping the original base and alignment points.

Compact Body and Lower Temperature Rise

Permanent magnets remove rotor copper loss. The result is a smaller volume at the same rating and a temperature rise lower by roughly 20 K versus three-phase asynchronous motors, which helps insulation life and bearing grease stability.

What Is the Step-By-Step Replacement Process?

A smooth retrofit follows a simple flow: confirm ratings, prepare the base, wire and set the drive, then commission with a short checklist. This keeps downtime short and avoids chasing faults that come from parameters, not hardware.

Step 1 — Confirm Electrical and Mechanical Ratings

Match rated voltage and frequency, check the power/torque point, and confirm IE-class efficiency. PMSM lines offer IE4-level efficiency with variable-frequency vector control, plus options like PTC/PT100, encoder feedback, and IP54 or higher protection for harsh rooms. Cooling types IC411 and IC416 are common, and installation forms cover IMB3/IMB5/IMB35.

Step 2 — Prepare the Mounting Base

Clean the baseplate, verify bolt-hole spacing, and check shaft height. Because the installation dimensions match, alignment is usually straightforward. Some PMSM bodies are shorter and lighter, which makes handling easier, but shaft and keyway tolerance still deserve a quick gauge check before coupling.

Step 3 — Electrical Connections and Drive Setup

PMSM runs with a VFD. Configure vector control per nameplate, set current and speed limits, and wire sensors as specified. This family’s high power factor (often 0.95 and above) lowers system current, which helps the upstream transformer and cabling. If you use closed-loop control, confirm the encoder type and scaling before first spin.

Step 4 — Commissioning and Test Run

Record baseline values: stator current at your key setpoints, winding temperatures, vibration, and power factor. PMSM maintains high efficiency from about 25% to 120% load, so expect strong part-load numbers and stable pressure tracking on compressors. Keep this baseline as your PMSM motor maintenance reference.

What Benefits Will You See After the Retrofit?

You care about electrical bills, uptime, and the time a tech spends with a grease gun. PMSM shifts all three in your favor.

Higher Efficiency and Power Factor

Rated efficiency is typically 2%–5% higher than equivalent induction motors, with power factor up to about 0.95 or above. Lower current trims copper losses across the system and may reduce reactive compensation hardware. In many plants, system energy savings of roughly 5%–30% appear when PMSM replaces low-voltage high-efficiency induction motors.

Cooler Running, Smaller Size, and Quieter Rooms

A PMSM’s lower temperature rise and higher power density mean a more compact frame and steadier thermal profile under swing loads. Less heat and balanced torque often translate to less noise and longer bearing life at the same duty.

Drive-Friendly Speed Range and Soft Behavior

With vector control, PMSM gives continuous adjustable speed and high starting torque with small starting current. That helps heavy starts and frequent cycling without hammering the grid, and it supports tight pressure bands on compressor rooms.

Which Mistakes Should You Avoid During the Swap?

Retrofits fail for predictable reasons. You can dodge most with a short “do-not-skip” list.

Skipping PMSM-Ready VFD Parameters

Do not run direct on line. Use a VFD with PMSM vector control and load the correct motor model parameters. Verify sensor wiring and scaling before full-load tests.

Ignoring Cooling Paths

Match cooling type (IC411 or IC416) and keep airflow clear. PMSM runs cooler, but blocked ducts or recirculating hot air still raise winding temperature, which chips away at magnet stability.

Overlooking Mechanical Fit Details

Seat number may match, yet body length can differ. Always check outline drawings and coupling dimensions, then torque fasteners to spec. It sounds obvious; it saves a Saturday.

Can You See a Real-World Compressor Case?

Take a common scenario: an aging induction motor on a variable-demand compressor. A same-frame PMSM unit with IE4-class efficiency and vector control replaces it. After alignment and parameter setup, measured results often show a lower temperature rise, a power factor around 0.95 or higher, and significant part-load savings because efficiency stays high from 25% to 120% of load. In general industrial service, system savings of about 5%–30% are reported compared with comparable induction setups. Link your spec notes to a permanent magnet motor for air compressor to check cooling, protection, and available options before ordering.

Who Is Qingdao Enneng Motor Co., Ltd.?

Qingdao Enneng Motor Co., Ltd. focuses on R&D and manufacturing of permanent-magnet motors for industrial duty. The portfolio covers low-speed high-torque, constant-speed, and direct-drive lines with IEC installation dimensions and variable-frequency vector control. Options include encoders, PTC/PT100, and IP54 or higher protection, across IC411 and IC416 cooling. Efficiency targets reach IE4 levels with high power factor, supporting lower current and cooler running. Applications span mines, rubber processing, water facilities, conveyors, compressors, and more. If your site needs tailored voltage classes, frame sizes up to medium voltage, or special cooling, custom builds match torque, speed, and footprint to the existing base, so you get energy savings without a civil rebuild.

FAQ

Q1: How do you confirm a same-frame swap before purchase?

A: Match seat number, mounting form (IMB3/IMB5/IMB35), shaft height, and outline length on the PMSM drawing. Verify voltage, frequency, and cooling type.

Q2: What performance gains are typical after replacement?

A: Expect 2%–5% higher rated efficiency, high power factor near or above 0.95, and a lower temperature rise of about 20 K compared with similar induction motors.

Q3: Can you keep the existing VFD?

A: Only if it supports PMSM vector control and your feedback device. Otherwise, use a compatible inverter and load the motor parameters before commissioning.

Q4: What about part-load operation on compressors?

A: PMSM maintains high efficiency across roughly 25%–120% load, so cycling duty and light-load hours still run efficiently and quietly.

Q5: Where should you place the first internal link for buyers?

A: Use early context to point readers to specs, for example this page on replace induction motor with PMSM, then reference maintenance and application details later to spread links across the article.