Does your factory’s power bill keep going up every month? Your air compressor might be the main reason. These industrial workhorses can use as much as 40% of your plant’s total energy. For a long time, factories just accepted this cost. It was part of doing business. But that’s changing now. A big change is happening on factory floors. It’s driven by a smart piece of technology: the permanent magnet motor. This isn’t a small improvement. It’s a whole new way to build a motor. It gives you real efficiency that directly cuts your running costs. Let’s look at how this technology works. We’ll see why it’s becoming the top choice for factories that watch their spending.

The Hidden Energy Drain in Your Factory

Most plant managers know air compressors cost a lot to run. But few see how much energy is truly wasted. The problem often sits with the standard induction motors. These have been the industry’s go-to for years. They’re strong and reliable, but they’re not clever with electricity.

An induction motor makes its magnetic field by pulling current from the power supply. This process naturally wastes some energy, especially inside the rotor. This waste is called slip. It makes the motor less efficient. Here’s the real issue. This inefficiency gets much worse when the motor runs below full power. Think about your own compressor. How often does it actually run at 100% load? In most places, demand goes up and down all day. During those times of partial load, which can be most of its day, a standard motor’s efficiency falls off a cliff. You end up paying for electricity that makes nothing but heat and bigger bills.

Why Your Old Compressor Is Costing You More Than You Think

The money drain isn’t just from power. The inefficiency of a standard motor makes extra heat. This heat wears out parts like bearings and insulation faster. What does that mean for you? More maintenance stops, a higher chance of surprise breakdowns, and a shorter life for your machine. You’re not just paying more for electricity. You’re also facing more repair bills and possible production halts. It’s a triple hit to your finances.

How Does a Permanent Magnet Motor Actually Save Energy?

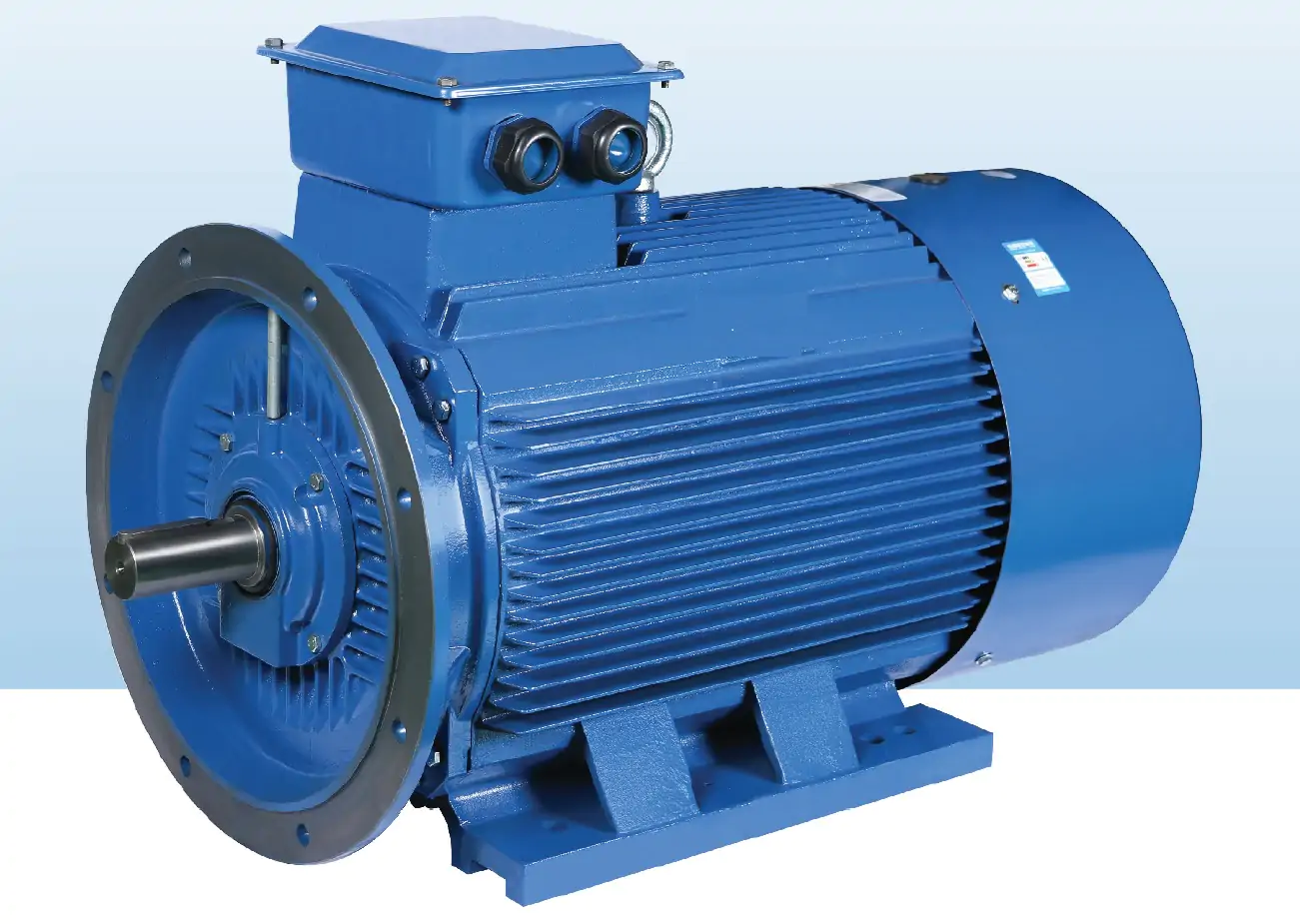

The secret sits in the magnets. A permanent magnet synchronous motor (PMSM) has strong rare-earth magnets built into its rotor. These magnets create a steady magnetic field all by themselves. They don’t need any electrical help from outside. This single difference changes the whole game.

Because the rotor’s magnetic field is always there, the motor cuts out the main energy loss found in induction motors. There’s no need to create a magnetic field, so there’s no slip. Much less energy turns into heat. The motor locks in perfectly with the spinning magnetic field from the stator. It turns more of the electrical energy it uses into real mechanical work. It’s a straighter, cleaner way to make power.

The Part-Load Performance That Makes the Difference

This is where you save real money. All motors work okay at full load. But a PMSM keeps its high efficiency even when running at partial load. Look at a standard efficiency chart. A normal induction motor might drop from 90% efficiency at full load to under 80% at half load. A permanent magnet motor is different. It can stay above 94% efficient across a wide range, from about half load to full load.

Most industrial compressors live in this partial-load zone. They spend most of their time there. So the PMSM fits real life much better. It gives you great performance where you actually work, not just in a perfect test.

What Does This Efficiency Mean for Your Bottom Line?

Let’s turn those technical wins into clear numbers. Swapping a standard 100 horsepower air compressor motor for a permanent magnet type can usually cut energy use by 15% to 30%. In a plant that runs all day and night, that percentage means a huge amount of money every year.

Here’s a real example. Imagine a factory with a $50,000 yearly electricity bill for compressed air. A safe 20% saving would put $10,000 back in the budget each year. That saving often pays for the motor upgrade in less than two years. After that, the savings go right into your profits. Plus, many governments and power companies give cash back for installing efficient gear. This can make the payback time even shorter.

Beyond Energy: The Ripple Effects of a Better Motor

The good stuff doesn’t stop at the power meter. Permanent magnet motors run cooler than old-style induction motors. Less heat means things like lubricants, insulation, and bearings last longer. This directly leads to lower maintenance costs over time and fewer surprise stops. The better reliability also stretches the compressor’s working life. It protects your big investment for more years. You get a system that’s not only cheaper to run but also stronger and more trustworthy.

Are Permanent Magnet Motors a Good Fit for Your Operation?

You might ask if this technology is right for your specific factory. The simple answer is that permanent magnet motors help most where demand changes. If your air use goes up and down during a shift or across the week, you will gain a lot.

They are a great pick for brand new compressor setups. They give you a modern, high-efficiency base. They are also a smart upgrade for older compressors that use standard motors. This is extra true if those units are getting old or need a big repair. It’s a chance to fix maintenance problems and save energy all at once.

Key Questions to Ask Before You Switch

Before you decide, it’s smart to check a few things. First, look at your compressor’s load profile. How much time does it spend at full power versus part power? The more time at part load, the more money you can save. Next, know your local electricity rates and any efficiency rebates you can get. Finally, when you look at different motors, don’t just see the first price. Look at how the motor is built, the quality of its bearings, and the maker’s name. A little higher cost at the start for a tougher motor can make sense if it lasts longer and works better over time.

A Partner in Industrial Efficiency

For factories ready to make the change, picking the right technology partner matters a lot. Qingdao Enneng Motor Co., Ltd. focuses on making high-performance permanent magnet motors for industrial jobs. Their motors are made to handle the tough life of a factory. They provide the strong performance needed for machines like air compressors, water pumps, and other industrial drives. The company works on new ideas and reliability. It aims to give solutions that help businesses use less energy and run better.

FAQ

Q1: How much can I really save with a permanent magnet motor on my air compressor?

A: Your exact savings depend on how you run things, but most factories cut their compressor’s energy use by 15% to 30%. The investment often pays for itself in under two years.

Q2: Do these motors require special maintenance?

A: Not really. They often need less care. Their simple design with no brushes and cooler running leads to less wear on parts. This means fewer maintenance visits and lower costs.

Q3: Can I retrofit a permanent magnet motor onto my existing compressor?

A: Yes, you often can. Putting a new motor on an old compressor is common and makes good financial sense. This is especially true if your current machine is still in good shape but has an inefficient motor.

Q4: Are permanent magnet motors reliable under heavy industrial use?

A: Yes, they are. They are built for hard factory life. Their strong build and cooler running usually give you a longer life and better uptime than standard motors.

Q5: How does the initial cost compare to a standard induction motor?

A: The first cost is usually higher. But see this as a spending that pays back. The big energy savings and lower maintenance costs mean the total amount you spend over the motor’s life is almost always lower.