Power range | 25‐250KW |

Speed range | 200‐600r/min |

Voltage level | 380VAC |

Installation method | Foot mounted or according to customer requirement |

Cooling method | Natural cooling |

Protection level | IP54(Higher protection level can be customized) |

Item | Permanent magnet synchronous motor for rotor pump | Low speed asynchronous motor |

Rated power (KW) | 75 | 75 |

Rated voltage (V) | 380 | 380 |

Rated current (A) | 146 | 166 |

Synchronous speed (r/min) | 500 | 500 |

Efficiency | 0.96 | 90.8% |

Power factor | 0.99 | 0.75 |

Maximum torque multiple | 2 | 1.6 |

Locked rotor current multiple | 2 | 5.5 |

Noise (dB) | ≤80 | 83 |

Vibration (mm/s) | ≤2.3 | ≤3.5 |

Duty | S1 | S1 |

Protection level | IP54 | IP54 |

Center height (mm) | 355 | 355 |

Motor length (mm) | 748 | 1491 |

Weight | 696kg | 1512kg |

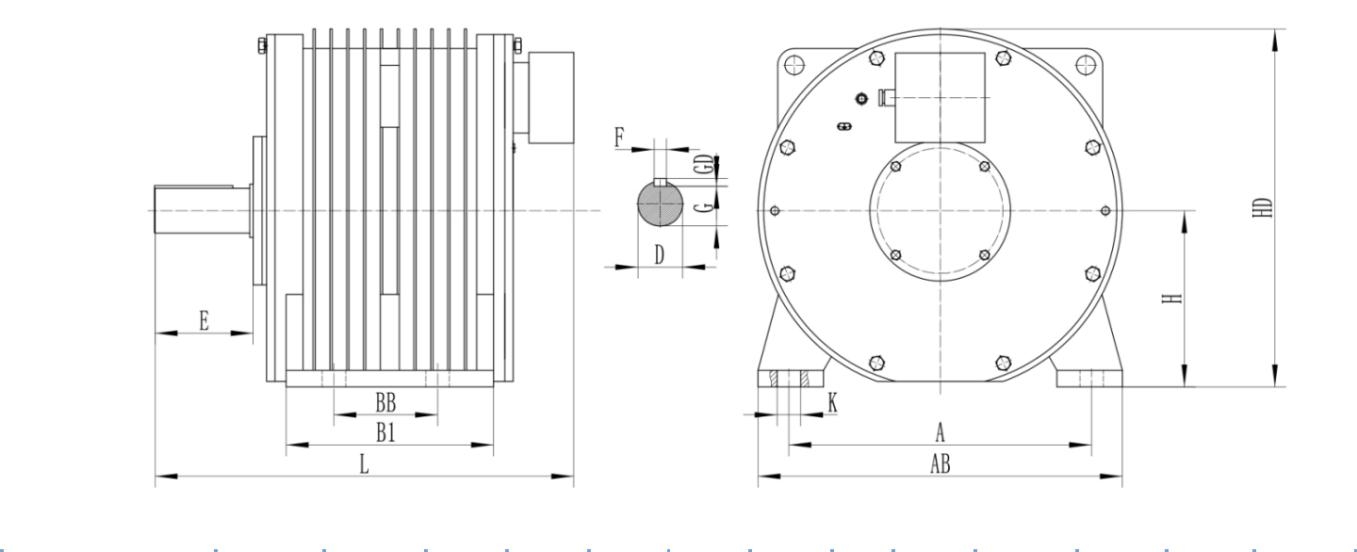

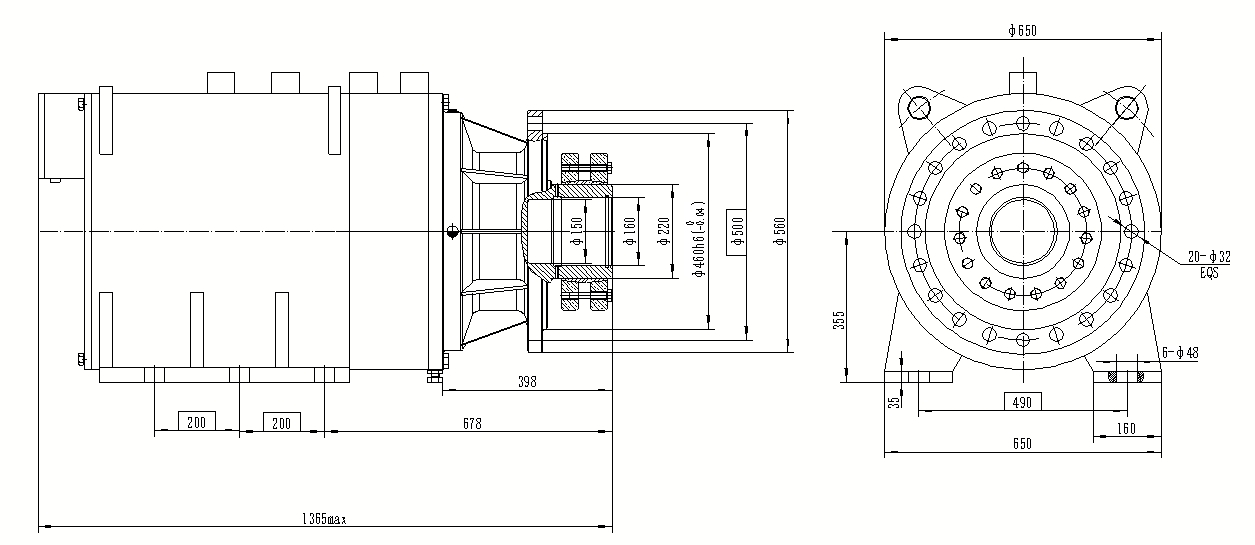

| Model | A | AB | B1 | BB | D | E | GD | F | G | H | HD | K | L |

| CPD550 | 540 | 650 | 18 | 37 | 80 | 17 | 14 | 2 | 71 | 355 | 640 | 42 | 748 |

Power range | 25‐400KW |

Speed range | 50‐100r/min |

Voltage level | 380V、660V、1140V、6kV、10kV |

Torque range | 5000-200000N·m |

Cooling method | Natural cooling、water cooling、forced air cooling |

Protection level | IP54(Higher protection level can be customized) |

| Parameters | Low speed and high torque permanent magnet motor drive system | High-speed motor + reducer + hydraulic coupling |

| Rated power (KW) | 132 | 132 |

| Rated torque (N. m) | 20000 | 20000 |

| Rated voltage (V) | 380 | 380 |

| Current (A) | 211.5 | 240 |

| Synchronous speed (r/min) | 60 | 60 |

| Efficiency (%) | 96.4 | 0.93×0.9=0.837 |

| Power factor | 0.9942 | 0.85 |

| Starting torque multiple | 1.5 | 1.5 |

| Maximum torque multiple | 2.0 | 1.5 |

| Weight (t) | 1.8 | 3.2 |

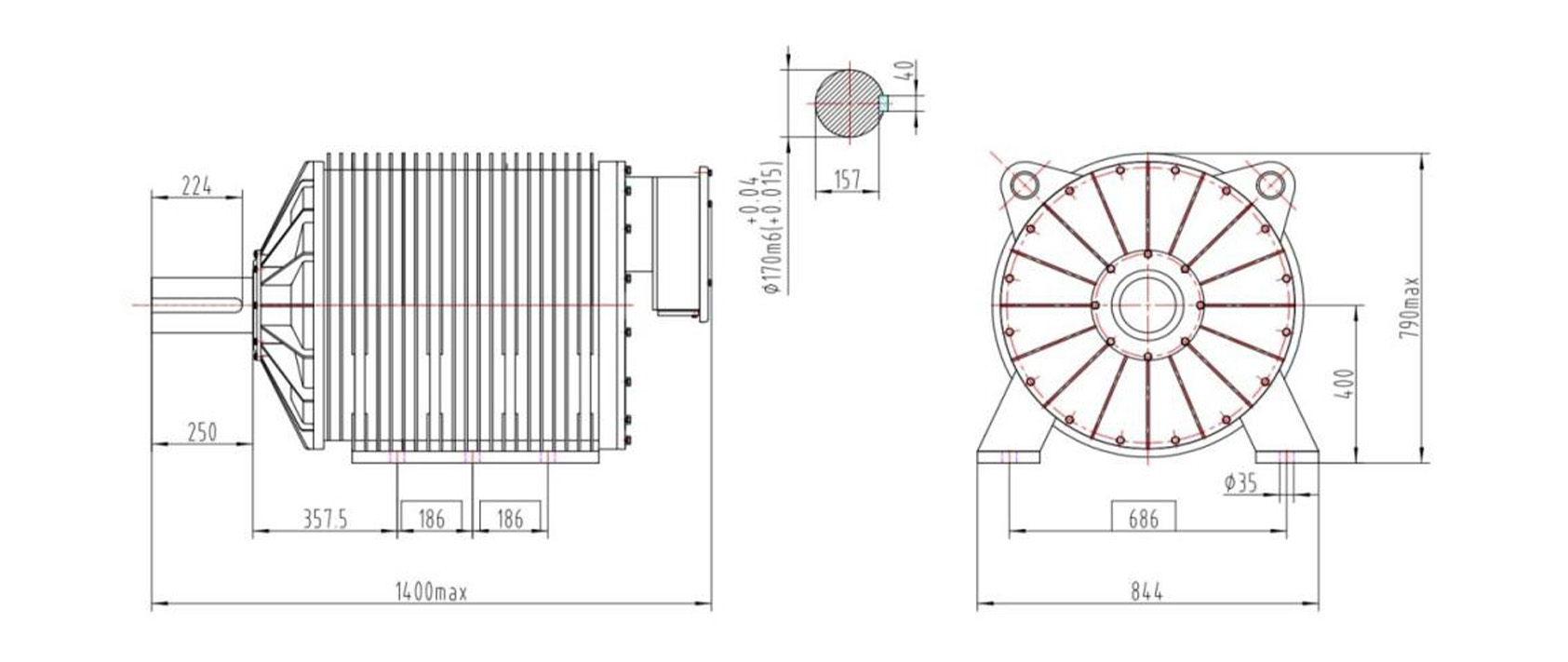

Power range | 25-250KW |

Speed range | 60-90r/min |

Voltage level | 380V |

Installation | Vertical installation or as per customer’s requirement |

Cooling method | Natural cooling、water cooling、forced air cooling |

Protection level | IP54 (higher protection level can be customized) |

| Parameters | Low-speed, high-torque permanent magnet motor drive system for air-cooled island | Asynchronous motor + reducer |

| Rated power (KW) | 132 | 132 |

| Rated torque (N. m) | 15000 | 15000 |

| Rated voltage (V) | 380 | 380 |

| Synchronous speed (r/min) | 81 | 81 |

| Maximum speed (r/min) | 91 | 81 |

| Efficiency (%) | 95.26 | 0.93×0.9=0.837 |

| Power factor | 0.987 | 0.88 |

| Current (A) | 237 | 240 |

| Starting torque multiple | 1.5 | 1.5 |

| Maximum torque multiple | 2 | 1.5 |

| Weight (t) | 1.7 | 2.6 |

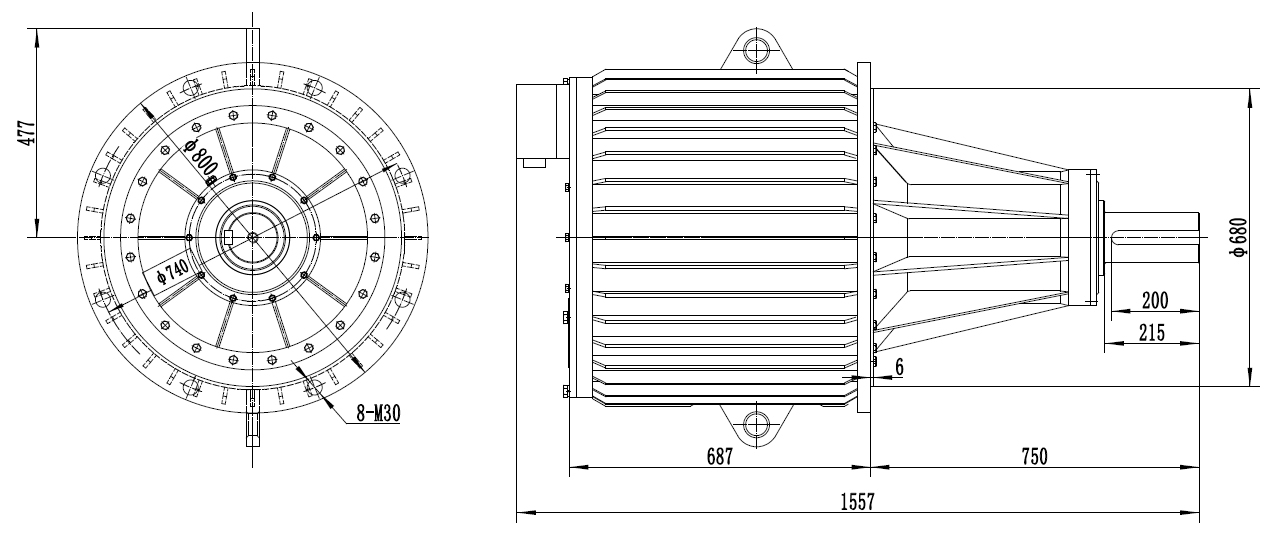

Power range | 75‐250KW |

Speed range | 6‐35r/min |

Voltage level | 380VAC、6kVAC、10kVAC |

Torque range | 30000-160000N·m |

Installation | Foot installation, according to customer requirements |

Cooling method | Forced water cooling |

Protection level | IP54 (higher protection level can be customized) |

| Parameters | Low speed and high torque permanent magnet motor drive system for mixing mill | Asynchronous motor + reducer |

| Rated power (KW) | 132 | 132 |

| Rated torque (N. m) | 84000 | 84000 |

| Rated voltage (V) | 380 | 380 |

| Rated speed (r/min) | 15 | 15 |

| Efficiency (%) | 96.16 | 0.95×0.9=0.855 |

| Power Factor | 0.9874 | 0.88 |

| Current (A) | 223.3 | 238.4 |

| Starting torque multiple | 1.5 | 1.5 |

| Maximum torque multiple | 2 | 1.5 |

| Weight (t) | 2.5*2 | 13 |

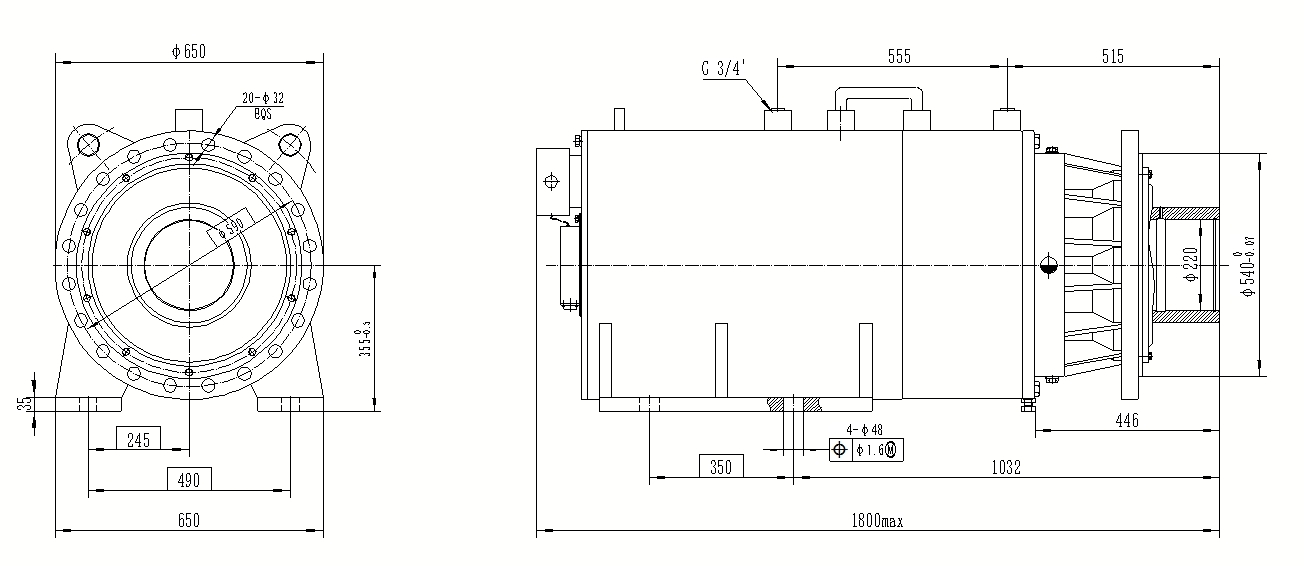

Power range | 25 -250KW |

Speed range | 5-40r/min |

Voltage level | 380V、6kV、10kV |

Installation | Foot installation or as per customer’s requirements |

Torque range | 30000-150000N·m |

Cooling method | Natural cooling, water cooling, forced air cooling |

Protection level | IP54 (higher protection level can be customized), conventional structure |

Parameters | Low speed and high torque permanent magnet motor drive system for rotary kiln |

Rated power (KW) | 90 |

Rated torque (N. m) | 57000 |

Rated voltage (V) | 380 |

Rated speed (r/min) | 15 |

Efficiency (%) | 95.6 |

Power Factor | 0.9894 |

Current (A) | 149.5 |

Starting torque multiple | 1.5 |

Maximum torque multiple | 2 |

Weight (t) | 1.7 |

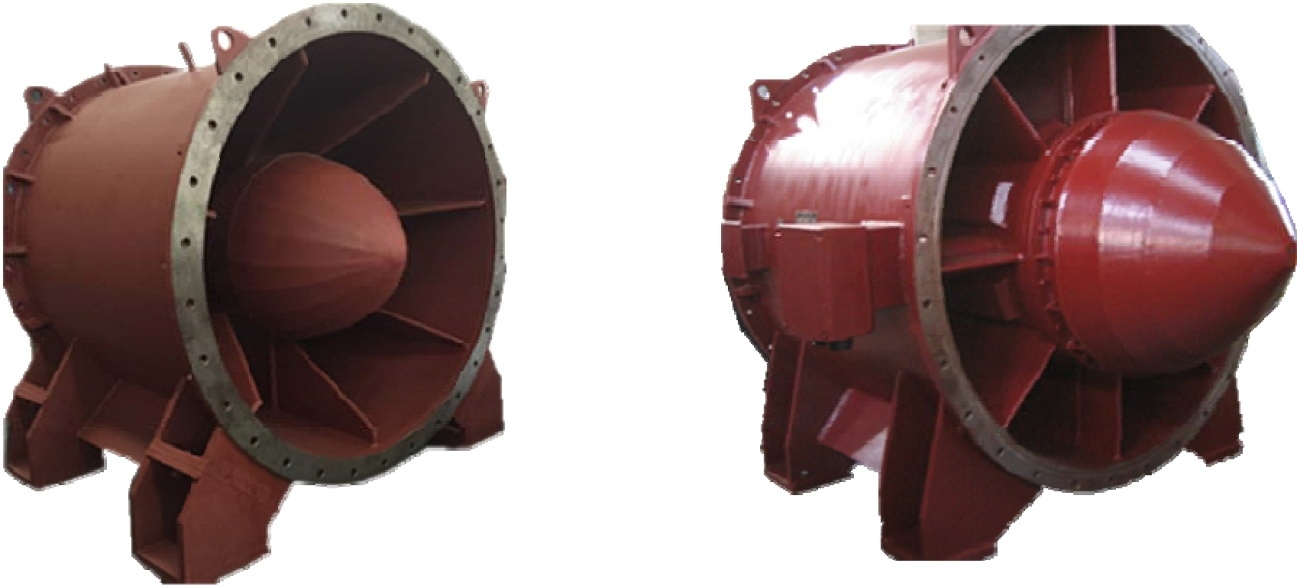

| Speed range | Power Range | Voltage range | Flow range | Installation dimensions and structure |

| 100-500r/min | 100-1000KW | 380-10000V | 1.5-15m3/s | According to customer requirements |

| Project | Permanent magnet motor for submersible crossflow pump | Low speed asynchronous motor |

| Rated power (KW) | 250 | 250 |

| Rated voltage (V) | 400 | 400 |

| Rated current (A) | 375.8 | 590 |

| Rated frequency (Hz) | 50 | 50 |

| Synchronous speed (r/min) | 250 | 250 |

| Efficiency | ≥97% | ≥92% |

| Power Factor | ≥0.97 | ≥0.66 |

| Maximum torque multiple | 2.0 | 1.6 |

| Stall current multiple | 2.0 | 5.0 |

| Noise (dB) | ≤80 | ≤85 |

| Vibration (μm) | ≤20 | ≤50 |

| Winding temperature rise (K) | ≤35 | ≤60 |

| Working system | S1 | S1 |

| Protection level | IP68 | IP68 |

| Core outer diameter (mm) | 850 | 990 |

| Length of effective part of motor (mm) | 1290 | 1980 |

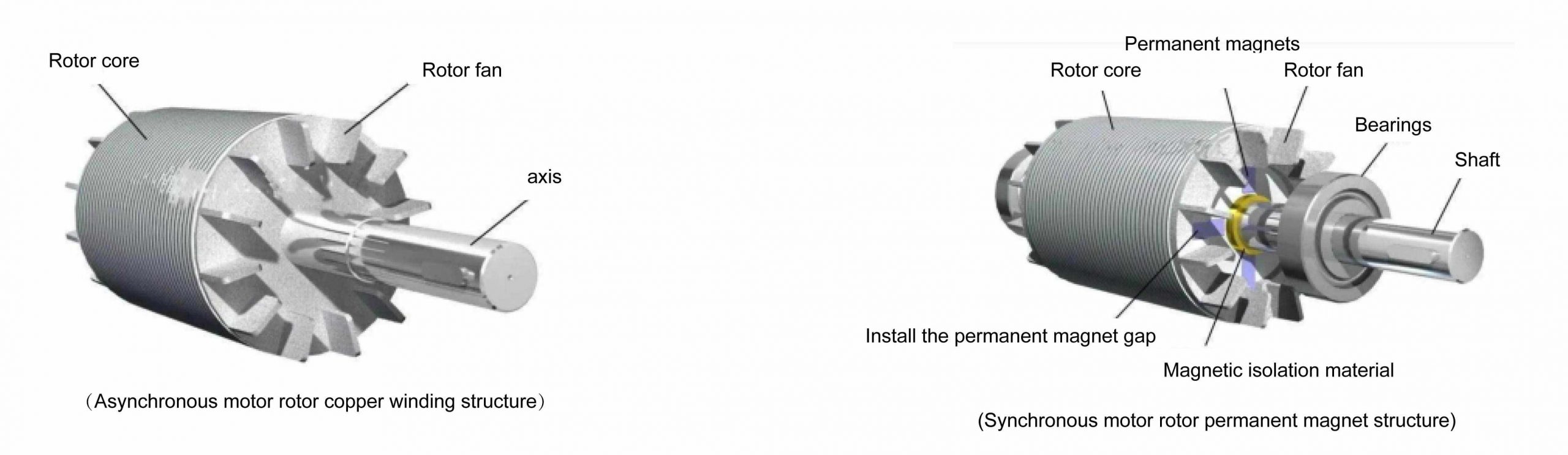

The motor + reducer transmission mode is a typical low-speed, high-torque load. When using an asynchronous motor, it is difficult to start and the starting current is relatively large. Especially when maintenance or a malfunction occurs, the steel balls and materials in the ball mill accumulate at the bottom of the drum for a long time, making starting more difficult and time-consuming.

After using the permanent magnet direct drive system, due to the large starting torque, the mill can be started smoothly under heavy load without the help of any auxiliary equipment, and the intelligent control system is used to adjust the motor speed according to the actual working conditions, thereby improving the process and increasing production efficiency. For the ball mill, after the drive system is modified, the power saving rate is more than 10%, which greatly reduces the production cost. In addition, the permanent magnet direct drive system has the advantages of maintenance-free, small footprint, saving a lot of space, and effectively reducing the cost of civil engineering investment.

At here, it’s all about giving the clients the best quality products.

© 2020 Qingdao Enneng Motor Co., Ltd.. All rights reserved.